Baked, Sliced, and Stitched: How Molchanovs Freediving Wetsuits are Made

Every stitch, seam, and type of neoprene in your wetsuit affects your performance—here's how they're engineered to meet different diving needs.

By Kristina Zvaritch

Contributors: Alexey Rogachev, Asya Kleshchevnikova, Oliver Christen-Drew

Editor: Deena Lynch

Photos provided © @junglefreediver.

Would you believe that the wetsuit protecting you on your deepest dives started as liquid rubber baked in an industrial oven? Neoprene—the material that makes scuba and freediving wetsuits possible—is prized for its insulation from cold, elasticity, and versatility. It's used in everything from orthopedic braces to laptop sleeves, but what exactly is this extraordinary material, and where did it come from?

What is Neoprene, Really?

In the early 1900s, a global shortage of rubber led producers to search for alternative materials to replace it, especially the American DuPont Corporation. An executive just happened to attend a lecture being given by a professor of chemistry at the University of Notre Dame, who had developed a plastic material. The professor was immediately recruited by DuPont and, along with other scientists, developed the mass-producible compound polychloroprene—a synthetic rubber substitute—based on the professor’s own material after many years of research.

Polychloroprene, known by the generic name neoprene, not only helped the Allied powers in World War II; in the early 1950s, it was introduced into diving wetsuits. Today, it’s the most common material in the world for—you guessed it—freediving wetsuits!

How Are Freediving Wetsuits Made?

Ever wondered how wetsuits are made? The Molchanovs Gear Product Manager, Alexey Rogachev, walked me through the process of how the wetsuits at Molchanovs are produced.

Raw Material

Fun fact—neoprene comes to the factory in liquid form. After it arrives, it's placed into a mixer and bakes like bread in an industrial oven; it's even referred to as a “loaf!” The factory then slices the loaf into sheets of the desired thickness: 1mm, 1.5mm, 3mm, 5mm, etc.

Lamination

These sheets are then laminated with nylon or Lycra, lining either only one side or both sides of the wetsuit, depending on its intended use. The lining makes wetsuits more durable, as bare neoprene is extremely delicate.

Wetsuits with no interior lining are referred to as having an "open cell" interior— the naked and pore-covered exposed part of the neoprene which adheres to your skin and prevents water from flowing in and out of the wetsuit. But if the exterior of the wetsuit doesn't have a lining, it has a smooth skin exterior—a surface without fabric. While this sheet still has an open cell side, it'll later receive a coating made of a special mixture, which fills in the pores and gives it the glide freedivers prize in the water (discussed further in ‘Finishing the Surfaces’).

Putting The Pieces Together

The pieces are then glued and stitched together to form the shape of the wetsuit. There are two methods used for different types of wetsuits.

Glued and Blind-Stitched (GBS)

The neoprene in thicker (1.5mm+) wetsuits is glued and blind-stitched (GBS). This method involves gluing the neoprene panels together, then blind-stitching them—the needle only goes partway through the neoprene without penetrating all the way through to the other side. If the wetsuit has interior or exterior fabric lining, that fabric is stitched separately using a flatlock stitch, which only goes through the fabric layer and not the neoprene itself.

Flatlock stitching on the Molchanovs SPORT Wetsuit Double-Lined.

Flatlock stitching on the Molchanovs SPORT Wetsuit Double-Lined.

Neither of these stitching methods fully penetrates the neoprene, which keeps water from having another channel to enter the wetsuit. The seams can then be reinforced with inner tape or external liquid seams to make them as watertight as possible and extremely elastic.

Heat Tape + Glue

This is a new method at Molchanovs that’s used on thinner wetsuits and will slowly replace GBS on thicker wetsuits. No threads, external or internal (blind), are needed—the wetsuit is glued, and then a thin elastic tape is applied along the inside of the seams. This tape reinforces the seams and prevents water from entering while keeping the wetsuits as elastic as possible due to the absence of threads in the construction.

Finishing the Surfaces

The final step? Adding the surface treatments—details that make all the difference underwater. Surface finishing depends on the wetsuit type: while most wetsuits are complete after stitching, performance wetsuits need an additional specialized treatment.

Outside-Lined and Double-Lined Wetsuits

Wetsuits with lining on the outside protect it from scratches and tears, while the open cell interior sticks to your skin and keeps you warm. © @b.blanked.

Wetsuits with lining on the outside protect it from scratches and tears, while the open cell interior sticks to your skin and keeps you warm. © @b.blanked.

Outside-lined wetsuits leave the inner open cell unfinished, so the open cell interior adheres to the skin and seals tightly against water from flowing into the wetsuit. Although very warm, the sticky interior of the wetsuit needs lubricant to put on. The outside is lined with fabric, keeping it safe from accidental scrapes.

Wetsuits with double lining have fabric laminated onto both the interior and exterior.

Wetsuits with double lining have fabric laminated onto both the interior and exterior.

With double-lined wetsuits—the most durable types for freediving—fabric is laminated onto both sides. This keeps the outside safe from cuts and scrapes against the outer environment, but also allows you to put the wetsuit on completely dry; no lubrication required!

Inside-Lined Wetsuits

The glide skin coating of the Molchanovs PRO Inside-Lined Wetsuit helps athletes glide in the pool and during freefall. © @oceanbrodie.

The glide skin coating of the Molchanovs PRO Inside-Lined Wetsuit helps athletes glide in the pool and during freefall. © @oceanbrodie.

Inside-lined wetsuits, used for optimal performance, feature an inner fabric lining lamination to make them easier to put on and for extra durability—after all, bare neoprene needs some reinforcement. However, after the wetsuit is in its final form, the outside smooth skin receives a special glide skin coating (also known as SCS—Super Composite Skin, developed by Yamamoto for premium neoprene). This treatment ensures it slips seamlessly through water, making your freefall and glides in the pool ultra-hydrodynamic.

Unlined Wetsuits

Wetsuits with no lining on either side of the wetsuits are referred to as “unlined” wetsuits. Since there’s no lining to reinforce either side of this type of wetsuit, it is extremely delicate and requires extra special care when putting it on (lubrication is a must!) and taking it off. Unlined wetsuits are typically used for competitions in colder waters, where the bare open cell interior of the wetsuit clings to the skin, keeping freedivers warm and preventing water from flowing in and out. The exterior smooth skin is treated with the same glide skin coating as inside-lined wetsuits for optimal underwater performance.

Different Types of Neoprene in Freediving Wetsuits

In freediving, the neoprene used is crucial because we are constantly diving and exposing our wetsuit to pressure underwater. Neoprene contains millions of bubbles, and these bubbles are contained within a fragile wall of material that keeps the gas within these bubbles intact. As you dive and the bubbles within the neoprene compress. High-quality freediving-specific neoprene is resistant to these types of pressure changes, while the bubbles in triathlon or surfing wetsuits (which aren’t designed to be exposed to high pressure) will quickly burst, rendering your wetsuit into a wet rag in a short period of time.

While there are many different types of neoprene brands, Molchanovs uses two: Yamamoto and JAKO, both of which use limestone-based neoprene. Limestone-based neoprene offers performance advantages over petroleum-based alternatives—it's more flexible and warmer, has more bubbles to absorb less water, and is lighter and more comfortable! Some limestone-based neoprene producers also utilize renewable energy sources in their manufacturing processes. But what's the difference between Yamamoto and JAKO?

Yamamoto

Yamamoto is a brand name that’s widely recognized in the freediving community for their premium neoprene. There are numbers that come after the Yamamoto name to indicate the grade of neoprene and its flexibility (and naturally, its cost). For freediving wetsuits, Yamamoto 39 and 45 are the most common. Other grades offer different levels of flexibility and durability, but they’re more targeted for wetsuits used in scuba, triathlon, kayaking, and other watersports.

PRO Line wetsuits use Yamamoto 45 for maximum performance in competition. © @garrettandrewmoss.

PRO Line wetsuits use Yamamoto 45 for maximum performance in competition. © @garrettandrewmoss.

Molchanovs uses Yamamoto 45 in its PRO Line wetsuits because 45 is softer, stretchier, and has better thermal insulation than 39, making it an excellent choice for competition use. However, wetsuits with Yamamoto 45 are also very delicate and need more care when putting them on and taking them off. These wetsuits' lifespan depends on a freediver’s level, the number of deep dives they do, how thick the wetsuit is, and how the wetsuits are maintained (covered in the next section).

JAKO Neoprene

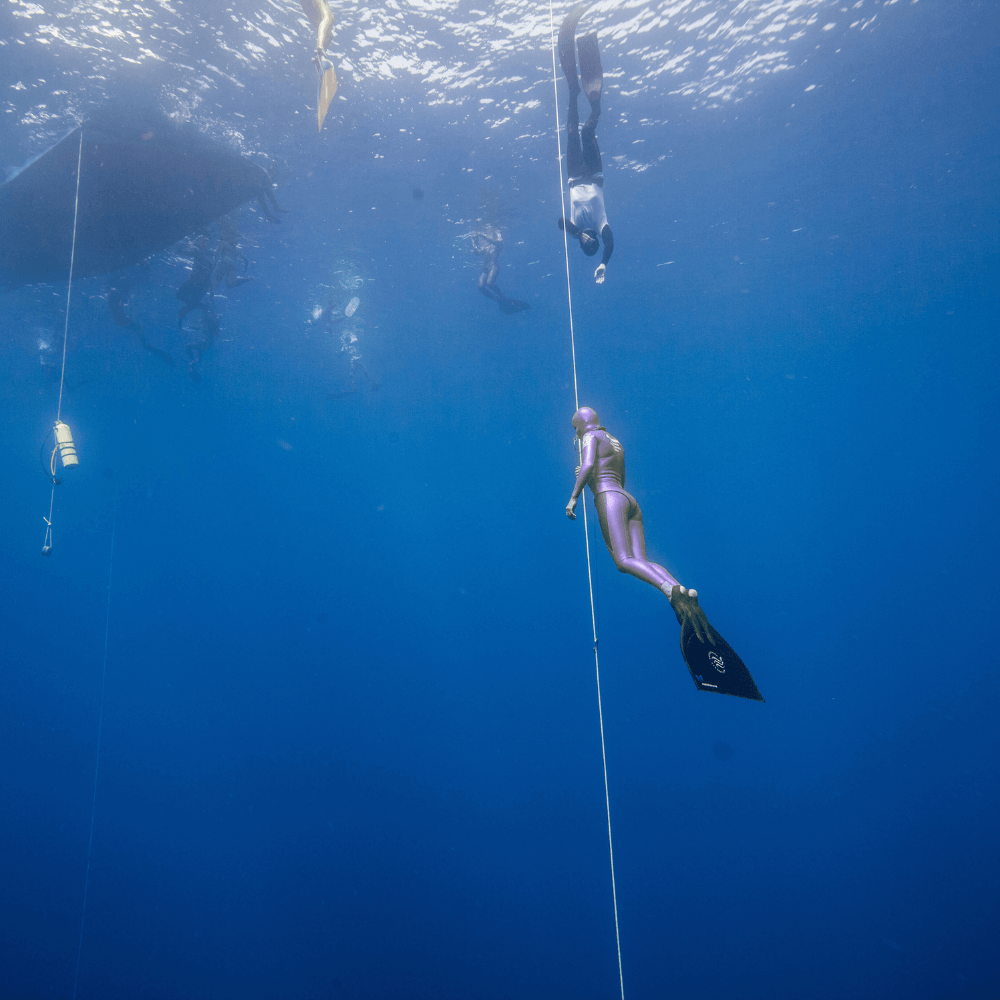

The SPORT Inside-Lined Wetsuit pairs JAKO neoprene with a glide skin coating—balancing performance with value. @junglefreediver.

The SPORT Inside-Lined Wetsuit pairs JAKO neoprene with a glide skin coating—balancing performance with value. @junglefreediver.

JAKO is also a popular neoprene brand name for freediving wetsuits. Compared to Yamamoto 45, it’s a bit stiffer, but with the right tailoring, wetsuits with JAKO neoprene can feel more elastic than ones made with Yamamoto 39. JAKO neoprene is also more resistant to compression at depth, which is why it’s the chosen brand for Molchanovs SPORT Line wetsuits—aimed at lifestyle freedivers (safety divers, underwater photographers, instructors, etc.) or for those who train and dive recreationally.

Extending the Life of Neoprene

Regardless of which neoprene type you choose, proper care is essential for maximizing your wetsuit's lifespan. For all types of freediving wetsuits, it's always important to rinse them thoroughly in fresh water after diving and dry them in the shade—not direct sunlight! Start with the exterior, then the interior, but for glide skin wetsuits, dry the exterior last. Putting a wetsuit on requires careful handling: wetsuits with an inner lining should be put on completely dry skin, while wetsuits with open cell on the inside require lubrication—make sure that your fingernails don't pierce the wetsuit while putting it on! If you have a wetsuit with a glide skin coating, it's a good idea to wear a protective layer over it (like a shirt) during extended periods under the sun, and always keep it away from Velcro, rocks, and rough surfaces. When storing your wetsuit, hang it on wide hangers in a cool, dry place.

For more specific information on how to care for each type of wetsuit, check out these equipment care instructions.

Which Molchanovs Wetsuit is Right for You?

Molchanovs SPORT Line wetsuits with double lining are up to the challenge of fun diving. © @novakfamily.

Molchanovs SPORT Line wetsuits with double lining are up to the challenge of fun diving. © @novakfamily.

If you’re a freediver who isn't in the competition scene, then SPORT Line wetsuits are the best option for you due to their durability, compression resistance, and value for money. If you're an amateur competitive freediver who isn't competing professionally, then the SPORT Wetsuit Inside-Lined will be your best bet, as it pairs value for money with great performance. But if you're making competitive freediving a big part of your life and need the best wetsuit for optimal performance, then higher-priced PRO Line wetsuits will be your ultimate performance tool, delivering maximum flexibility and hydrodynamic efficiency when every meter counts.

Whether you choose JAKO's durability or Yamamoto 45's cutting-edge performance, understanding the science behind your wetsuit helps ensure you're investing in gear that will keep you warm, safe, and performing at your best.

Be sure to check out our wetsuit guide if you need help choosing the right type of lining, thickness, and cut to suit your diving style!

Leave a comment